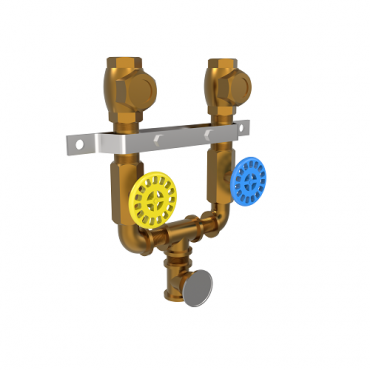

When the shower or eyewash is activated, the pressure drop on a diaphragm opens the steam control valve (V-3). Water and steam flow are established instantly heating water and condensing the steam. After exiting the heat exchanger, hot water enters the tempering valve (V-5) and then the mixing valve (V-1) where it is blended with cold water to produce an outlet of 80°F water. Steam valve remains closed should water supply be interrupted.

- Plant steam and water never mix-uses compact heat exchanger

- Standard pressure unit available for 45-60 PSIG steam pressure

- Low pressure unit available for 15-30 PSIG steam pressure

- Durable enclosure can be readily removed for service

- Conforms to OSHA and ANSI recommendations

- Designed to meet ASSE 1071 requirements

| Series | Therm-O-Mix Tepid Water Delivery System |

| Description | THERM-O-MIX® STATION LSP BPHE (15-30 PSIG STEAM) |

| Outlet Flow Rate Max | 25 GPM-95 LPM |

| Outlet Flow Rate Min | 3 GPM-11 LPM |

| Ambient Operating Temperature Max | 120°F-49°C |

| Ambient Operating Temperature Min | -30°F-34°C |

| Inlet Water Pressure Max | 90 PSIG-6 BAR |

| Inlet Water Pressure Min | 55 PSIG-4 BAR |

| Inlet Water Temperature Max | 80°F-27°C |

| Inlet Water Temperature Min | 40°F-4°C |

| Inlet Saturated Steam Pressure Max | 60 PSIG-4 BAR |

| Inlet Saturated Steam Pressure Min | 45 PSIG-3 BAR |

| Inlet Saturated Steam Pressure Low Pressure Max | 30 PSIG-2 BAR |

| Inlet Saturated Steam Pressure Low Pressure Min | 15 PSIG-1 BAR |

| Maximum Steam Temperature Max | 350°F-177°C |

| Cold Water Bypass Flow Rate | 24 GPM @ 25 PSI Pressure Drop |

| Water Inlet & Outlet Pipe Size | 1 1/4" NPT (F) |

| Steam Supply & Drain Pipe Size | 1" NPT (F) |

| Steam Consumption | 600 lb./hr @ 25 GPM Flow Rate, 20 lb./hr @ Idle |

| Condensate Discharge Rate | 12 GPH maximum |

| Pressure Drop Water Inlet | 25 PSI @ 25 GPM |

| Isometric View | Download |

| Front View | Download |

| Top View | Download |

| Side View | Download |

Disclaimer

All drawings and 3D models are provided for reference only and are not controlled documents. Files may not reflect current revisions or design intent and shall not be used for manufacturing, inspection, or certification. Only officially released ThermOmegaTech drawings and documents issued through the company’s controlled document system are considered authoritative.

All drawings and 3D models are provided for reference only and are not controlled documents. Files may not reflect current revisions or design intent and shall not be used for manufacturing, inspection, or certification. Only officially released ThermOmegaTech drawings and documents issued through the company’s controlled document system are considered authoritative.

.png)