The Thermostatic Mixing/Diverting Valve is designed to maintain or proportion flow based on temperature in mixing or diverting applications. In mixing applications where a controlled temperature outlet is required, the thermal mixing valve (M/D) will modulate between the hot and cold inlet feeds (ports “B” and “C”) to mix your fluid to the desired specified temperature exiting the “A” port. In diverting applications where the fluid must be directed from one section of a system to another, the thermal diverting valve (aka thermal bypass valve) will modulate inlet fluid temperature and divert return flow through a cooler/ heat exchanger or bypass it to a reservoir/ bypass loop when fluid temperatures are satisfied. This action assures rapid system warm-up, accurate control of fluid temperature, and reduced back pressure in the return.

| Aviation Radar Cooling | Fuel/Oil Cooler |

| Battery Cooling | Hydraulic thermal bypass |

| Cooling water control for radiator or heat exchanger | Loop-type circulation systems |

| Direct cooling with raw water | Lube oil cooling control |

| Direct injection water heating | Lube oil thermal bypass |

| Electronics system cooling | Temperature control for baths, wash basins, and sinks |

| Engine and compressor cooling system | Temperature mixing or diverting |

| Hydraulic fluid cooling systems | Thermal Management |

| Hydraulic power units (HPUs) | Water saving applicationsl |

- Exclusive self-actuating Thermoloid® wax blend thermal actuator

- Heavy-duty – rugged construction

- Compact and low mass for fast response

- Operates in narrow temperature band

- Standard valve material is bronze or stainless steel

- Self-operating – no external power source required

- Minimal maintenance needed

- Wide temperature range

- Easy installation

- Few moving parts – Reduce system wear

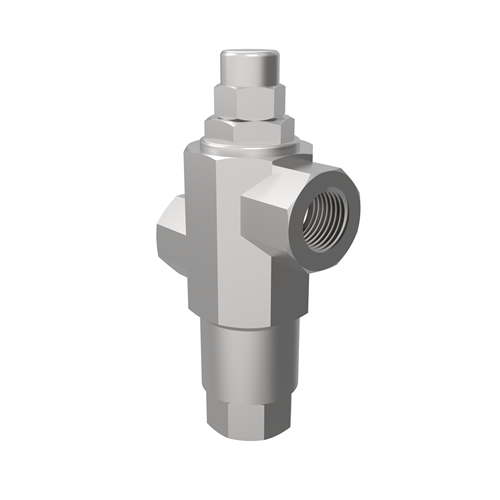

| Series | Mixing and Diverting Valves |

| Description | 1/2" M/D Valve - all 316 SS construction |

| Size | 1/2" NPT |

| Width-in | 2.62 |

| Width-mm | 67 |

| Height-in | 4.9 |

| Height-mm | 124 |

| Weight lb | 1.5 |

| Weight kg | 0.6 |

| Cv | 2.7 |

| Maximum Operating Pressure | 350 PSIG (24 BAR) |

| Maximum Temperature | 250°F (121°C) |

| Opening Temperature | 35°F, 45°F, 50°F, 60°F, 70°F(+/- 8°F), 85°F, 90°F, 100°F, 105°F, 110°F, 125°F, 130°F(+/- 8°F), 135°F, 147°F (+/- 8°F), 152°F (+/- 8°F), 160°F, 170°F, 190°F, 200°F, 205°F, 210°F (1.7°C, 7.2°C, 10°C, 15.6°C, 21.1°C, 29.4°C, 32.2°C, 37.8°C, 40.6°C, 43.3°C, 51.7°C, 54.4°C, 57.2°C, 63.9°C, 66.7°C, 71.1°C, 76.7°C, 87.8°C, 93.3°C, 96.1°C, 98.9°C) |

| Closing Temperature | Unless otherwise noted, during operation, the valve will modulate the Cold side (C port) closed at 5°F below the set-point, and the Hot side (B port) closed at 5°F above the set-point. |

| Body Material | 316 Stainless Steel |

| ANSI Body Compliance | 300 Class |

| Seal Material | Available in Buna-N, EPDM, Viton, or Fluorosilicone |

| Isometric View | Download |

| Front View | Download |

| Top View | Download |

| Side View | Download |

.png)